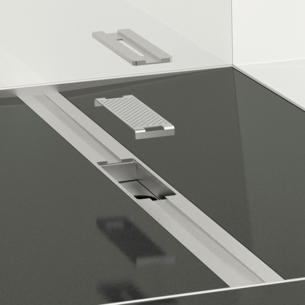

Tile-over shower tray Atrium

- Watertight tile-over tray in stainless steel

- Comprehensive integrated system for modern shower areas

- All water-bearing surfaces fully sealed during production

- Includes gradient wedges and siphon for drain connection

- 10 year guarantee on products used in water-carrying areas

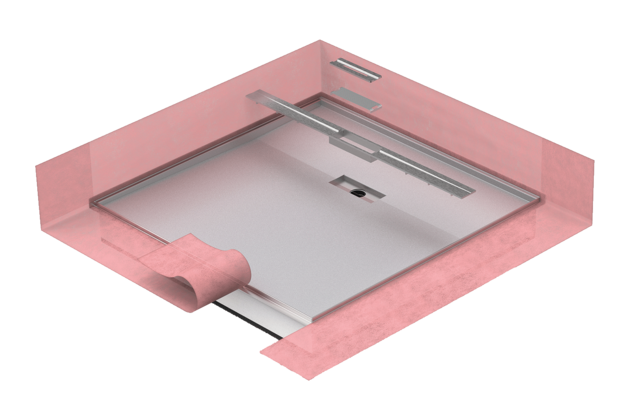

The fully leakproof integrated system Atrium

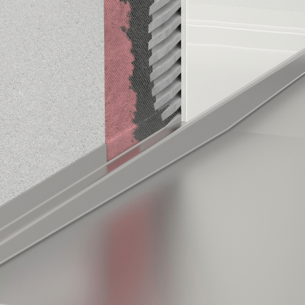

As an integrated system, our Atrium shower tray unites minimum installation effort with maximum watertightness thanks to a fully welded stainless-steel tray. This also does away with time-consuming sealing work. We always supply appropriate sealing collars to cover the transitions with the delivery; on request, the collars can be bonded to the shower tray during production. The Atrium system features the necessary gradient as standard, formed by the stainless-steel tray together with an XPS substructure, besides a flexibly adjustable siphon that can be connected to a drain pipe.

We provide a ten-year guarantee on our products used in water-carrying areas!

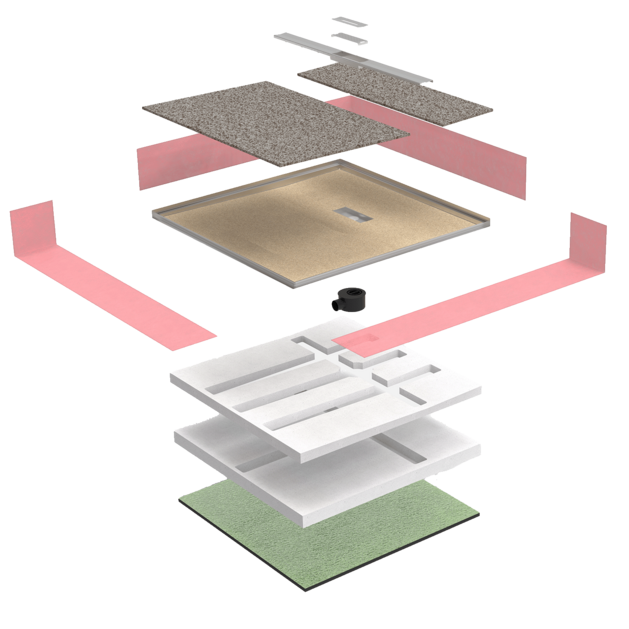

The Atrium shower tray is assembled as follows:

Prior to installation, the shower tray can either be placed into a recess in the screed or positioned on the floor before laying the screed. From the bottom up, installation of the tray is as follows:

- Wraparound sealing collars (always supplied, pre-mounted on request)

- Sanding during production (holding primer)

- Stainless-steel tray with gradient and surrounding 15mm edging

- Upper XPS gradient wedge

- Lower XPS block with cut-outs for the flexible orientation of the siphon

- Sound insulation mat

Once installed, the system can be directly tiled in the wall and floor area above the sealing strips and inside the stainless-steel tray. The Atrium shower tray is supplied together with a draining channel, which is attached to the stainless-steel tray with the help of a rubber seal. The polished stainless-steel profiles contain an insertable attachment that can be quickly and easily removed for cleaning.

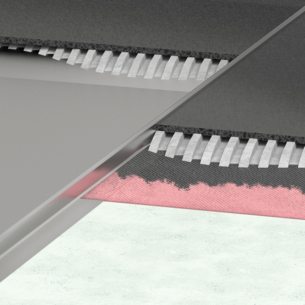

Adaptable in width, flexible in tile thickness

We provide the shower tray with fixed depths and widths of 900mm, 1,000mm or 1,200mm as standard. We can however also produce the tray in custom widths to meet your specific needs. Moreover, our shower trays are generally designed to hold tiles and slabs measuring between 6mm and 12mm thick.

If the use of a thicker material is planned, please inform us of this when placing your order. On request, we can produce the tray to hold tiles or slabs measuring up to 20mm thick.

Tile-over shower tray Atrium |

|

|---|---|

|

Widths |

900 mm 1.000 mm 1.200 mm individual on request |

|

Depths |

900 mm 1.000 mm 1.200 mm no individual dimensions |

|

Total height |

147 mm to top edge of covering By removing the XPS substructure, the the total height can be reduced to 67 mm. |

|

Inlet depths |

15 mm all round |

|

Materials |

Stainless steel (V2A) 1,5 mm V4A on request |

|

Possible coating thickness |

from 6 mm up to 10 mm as standard on request also available for up to 20 mm available |

|

Connector |

Corner version optionally left or right Niche |

|

Details |

We always supply appropriate sealing collars to cover the transitions with the delivery; on request, the collars can be bonded to the shower tray during production |