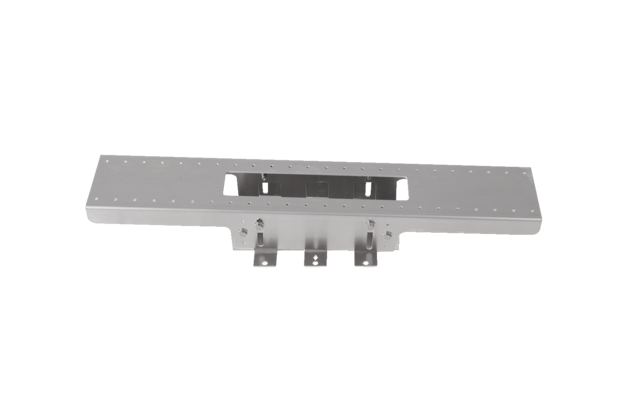

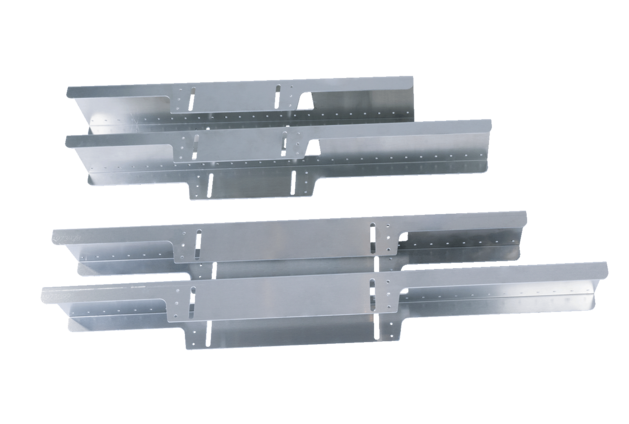

Height-adjustable Cavor Flex substructure for edge profiles

- Height-adjustable base designed to complement our edge-profile system

- Custom made to fit our watertight rubber lip holders

- Screwed directly to the roof edge

- Easy to adjust height and set gradient

- Resulting spaces can simply be filled with insulation

- Various models for individual design freedom

Cavor Flex – the simple way to tilt your roof edge

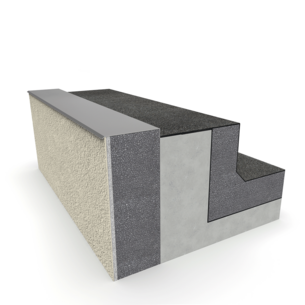

The structural fabric of roof edges and wall connections requires comprehensive and reliable protection from damp and moisture. Our custom-made Cavor edge profiles offer exactly that, while also enhancing the look of parapet walls. However, they cannot be placed directly on top of the roof edge. To make installation possible, we provide accessory parts developed in-house that fit the edge profiles, including our time-proven rubber lip holder and the new, highly flexible Cavor Flex substructure.

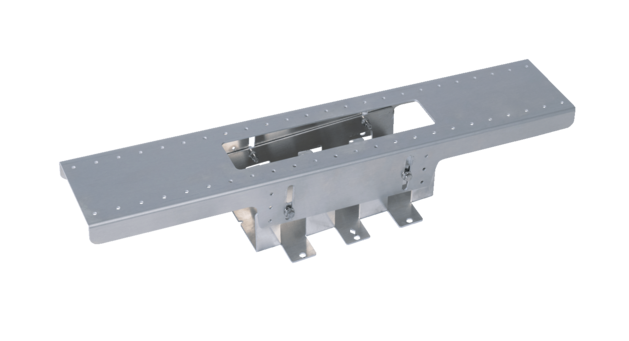

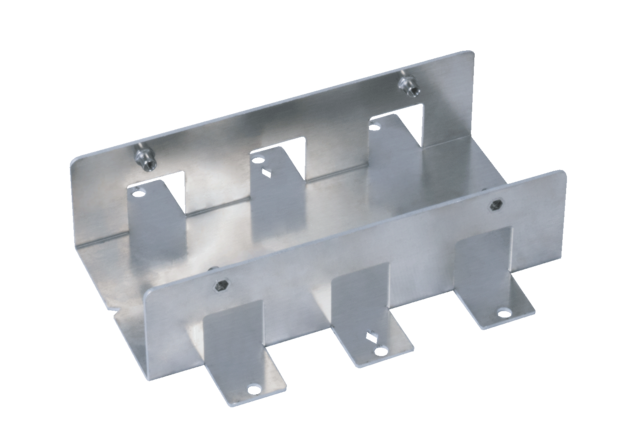

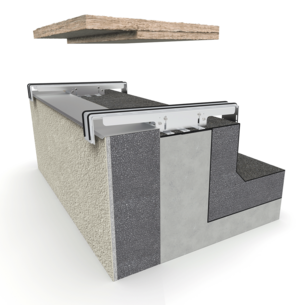

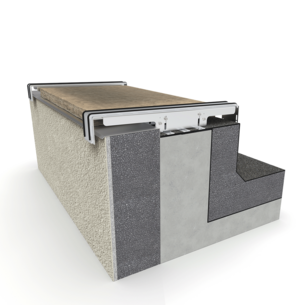

An interlocking system

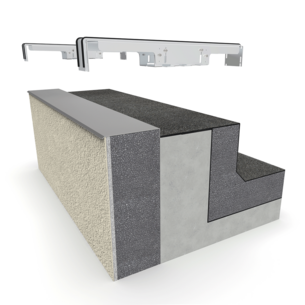

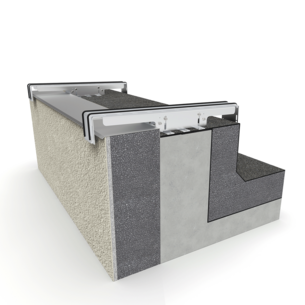

The product innovation serves as a height-adjustable substructure. Coupled with our rubber lip holder, which both supports and connects the edge profiles, the substructure creates an interface between the masonry and the profile. In the past, appropriate wooden planks that sloped towards the roof surface had to be mounted as a substructure before fitting the rubber lip holders on top. By comparison, the Cavor Flex can be screwed directly onto the masonry at selected points. The reduced material usage is not only sustainable, it also simplifies the otherwise time-consuming preparation and installation work on site.

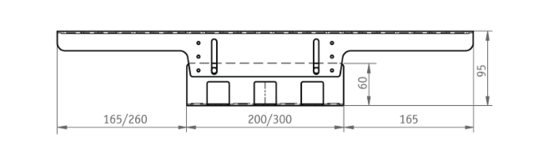

The substructure can be steplessly adjusted in height from 60mm to 95mm thanks to slotted holes, creating a gradient of up to 2°. Any accumulating water is directed to the roof’s dewatering solution rather than the façade. The Cavor Flex completely does away with the need to create a gradient using wooden planks as a substructure.

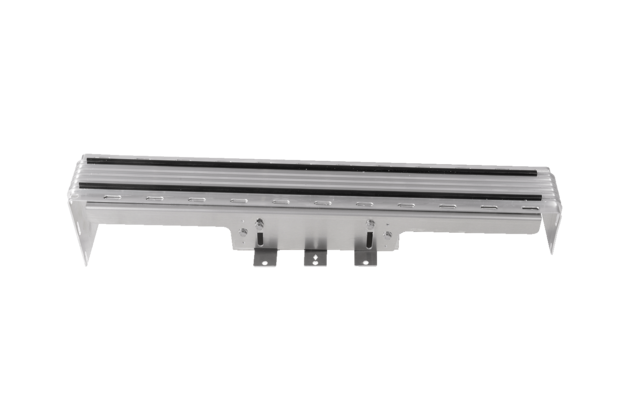

The Cavor Flex was conceived as a precise counterpart to our popular rubber lip holders. The aluminium groove profiles with pre-mounted rubber lips function as mounts and also rail connectors for the edge profiles. They are screwed to the substructure with great precision, which not only makes for sustainable material savings but also simplifies the installation work on site. The edge profile is then placed over the rubber lip holders.

Successful installation in just a few steps

1. The rebate profile is screwed down.

2. The first sealing layer is welded on, up to and over the rebate profile’s screwed side. The building structure is now already protected from rain.

3. The insulation and the rendering or bricks can be added

4. The height-adjustable Cavor Flex substructure with rubber lip holders is screwed down and can be steplessly adjusted to the right height

5. Any emerging spaces and the substructure itself can also be insulated

6. The actual parapet covering is mounted

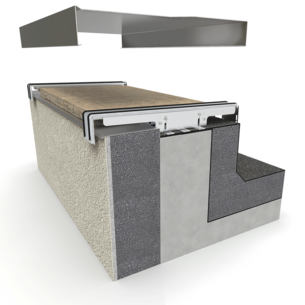

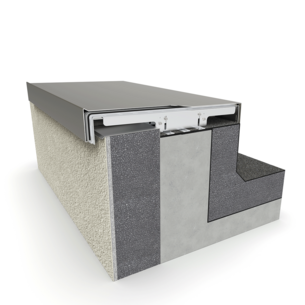

Complete independence between insulation and parapet cover

An optional cover profile helps save even more time. It can be screwed directly to the roof edge and creates a projection on the façade side. The profile helps build an initial seal along the edge of the roof. The cover plate aids the plasterer or bricklayer by acting as a protection and rebate profile for the subsequent insulation layer and façade. As the insulation and façade are to be added below the profile, work on the façade and the parapet covering can be carried out in parallel or separately.

The projecting sections of the substructure are available in various models to meet different site conditions. We also offer bespoke substructures to ensure every requirement is met. The Cavor Flex thus slots perfectly into our range of products for edge profiles and parapet coverings, which stand out thanks to their high quality and dimensional accuracy.

Custom cover in just a few clicks

Enter your specific measurements into our specially developed edge profile configurator and receive a ready-to-order summary of the edge profiles that are to be custom made, including all accessory parts required for installation.

Height-adjustable substructure Cavor Flex |

|

|---|---|

|

Projection 1 (top U-profile) |

165 mm 260 mm |

|

Projection 2 (top U-profile) |

165 mm |

|

Widths |

200 mm 300 mm |

|

Materials |

aluminium 2,0 mm |

|

Inclination |

Up to 2° ; 60mm – 95mm |

|

Details |

custom measurements decorative metal sheet |

|

Technical drawings |

|

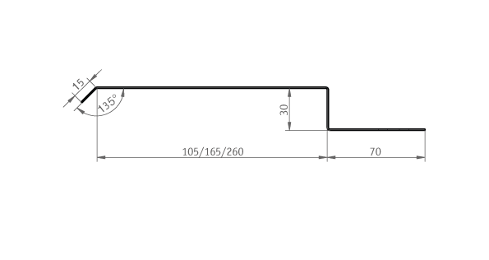

Decorative profile: |

|

|---|---|

|

Technical drawing |

|