When arranging garden and terrace spaces at home, plant boxes have always been very much in vogue, also as a way of adding a splash of green away from flower beds. They give outdoor areas a modern, contemporary look while consciously setting colourful accents. The 'Line’ plant box range from Richard Brink is the perfect solution here with its well thought-out, modular construction also ensuring the highest quality and stability.

Simply stable

Thanks to its individual elements, the aluminium boxes are easy to assemble and install. The screws are inserted through the inside flange of the respective segment and secured with nuts. The colour-contrasting pilaster strips positioned between the flanges add a special touch to the “Line” range. Besides their function as a connecting piece, they also strengthen the shell of the box. Both the side walls and the bottom plate are secured using screwed connections. Furthermore, the tie rods supplied with the boxes can be used to counteract even the largest loads for years to come. Drip trays that collect excess water are produced upon request. They also protect the ground on plastered and terrace areas from dirt and water marks.

The right choice for every preference

The company Richard Brink manufactures the modular plant containers using 2.0mm thick aluminium in heights of 400mm and 650mm – with a plastic coating. Both heights can be assembled in five different length and breadth constellations ranging from between 445mm to 1,390mm. Richard Brink’s range of goods with a colour finish can be combined just as easily. Customers can choose from two standard versions: with side panels in pure white (RAL 9010) and pilaster strips in iron mica (DB 703) or vice-versa. Upon request, the plant boxes from the ‘Line’ range can also be manufactured in any other RAL colour subject to an additional charge per colour to cover preproduction costs.

Protect against wind and weather

The articles offered by the metal products manufacturer appeal through their high durability. To ensure this level of durability also for plants facing extreme weather conditions, the modular plant containers can also be lined and insulated with 20mm-thick Styrodur, providing reliable protection against frost and dehydration and allowing customers to enjoy their green spaces for a long time to come.

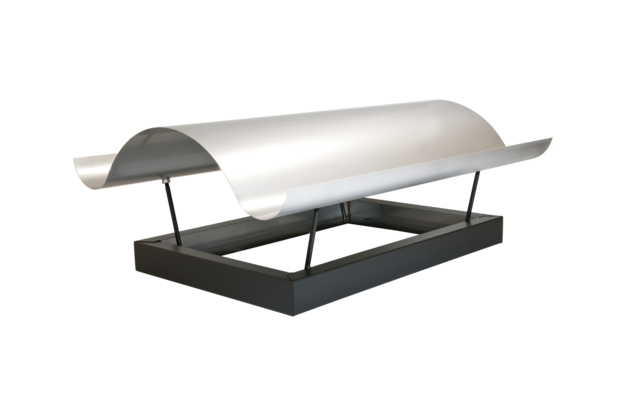

![[Translate to Englisch:] Erhöhte Zeltdach-Form aus Edelstahl [Translate to Englisch:] Kaminabdeckung mit erhöhter Zeltdach-Form](/fileadmin/_processed_/6/2/csm_teaser-dach2_f70f96f661.png)