Design elements are particularly effective when used in ornamental and showcase beds. This is true both for parks and golf courses as well as for private gardens. Gravel is often used to achieve the effect. But patterns and motifs only really unleash their full effect when different colours and textures are properly separated from each other. This is made possible with the flexible edging solutions made of 1.5mm stainless steel, aluminium or COR-TEN steel from Richard Brink. Standard edging solutions are available in lengths of 3m and heights of 100 or 150mm. The modular supporting bases allow for segments to be curved and laid as desired.

Precise preparation of elements

To create small-sectioned motifs using edging solutions, it is a good idea to make individual elements before laying them out in the garden area in question. The flexible rails can be rolled over the ground and formed into curves in this way, simplifying subsequent work on winding sections. Craftsmen use an angular grinder to cut the desired elements and piece them together. The ends of the 3 m long edgings each have a hole as standard, which matches up with the series of holes in the connector plates. This allows rails that have not been shortened to be easily extended by sticking piece together and screwing them in place. To connect cut elements, workers drill new holes and use the flexible connectors to secure everything. The connector plates fit each curve perfectly thanks to five perforated bending points. Overstretching allows them to be quickly broken up and shortened to the required width.

Fixing the rails

Accurate implementation requires as even a substrate as possible. The prepared motif templates are laid out on this substrate. The pre-fabricated edgings are then fixed to the ground using steel pins. The pins are nailed through the blanked supporting bases of the edgings, which prevent the elements from sinking into the earth. The picture is then formed by mounting the elements, starting with the smallest parts on the inside first and working out to the larger sections such as the outer edges of the design.

Filling in with gravel

The next step is to cover the areas with a concrete layer and then water them. In addition to acting as a clean layer for the gravel and therefore making it easier to maintain, this layer also serves as a weed barrier. Once the concrete has set, the gravel can be poured into the individual sections of the bed. Different types of sorting offer countless design possibilities – the selection ranges from subtle to high-contrast colours. The gravel texture should not include pieces that are smaller than 8 to 16mm, so the gravel cannot be sucked up by a leaf vacuum when the stones are cleaned. The easy-maintenance gravel area makes the finished bed a unique eye-catcher in the garden.

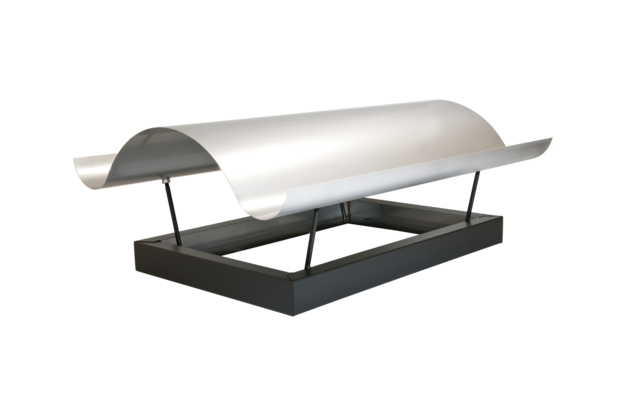

![[Translate to Englisch:] Erhöhte Zeltdach-Form aus Edelstahl [Translate to Englisch:] Kaminabdeckung mit erhöhter Zeltdach-Form](/fileadmin/_processed_/6/2/csm_teaser-dach2_f70f96f661.png)