Long-term exposure to precipitation can lead to sooting in a chimney. If the outer casing of the chimney is penetrated by water, tar and acids, repairs become necessary. This is why chimney caps are a good idea, especially in regions that experience heavy precipitation and rough weather. Richard Brink offers effective protection with its easy-to-handle, custom-made chimney caps.

Impressive system

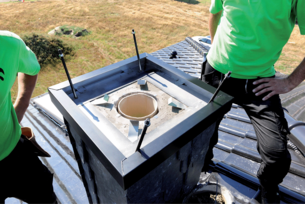

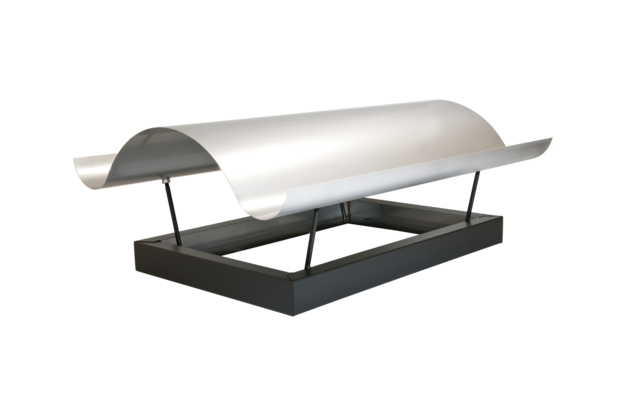

The chimney head can be covered with a type ‘RB-SA 1’ cap including shuttering frame – without damaging the chimney. There is also the option to combine the system with cladding suspensions, providing quick and stable cladding for the chimney: cap and cladding as if from one mould. This does away with the need to case and strip the concrete coping slab or follow a complicated installation procedure as with a conventional cap design.

Another version with a substructure, the ‘RB-SA 2’, can be bolted onto existing chimney heads with concrete slabs, and is also suitable for system chimneys. Installed quickly and easily, both caps provide permanent protection from the elements and improve the look of the roof.

Worry-free use

Extensive testing now confirms the impressive resilience of Richard Brink’s chimney caps. They meet all requirements set out in the DIN EN 16475-7 standard for worry-free use with exhaust gas systems that utilise fossil fuels. An independent test laboratory has tested and certified the components from the metal products manufacturer in terms of thermal load, soot fire resistance, corrosion resistance, pressure stability, wind load, ingress of rainwater, flow resistance, freeze and thaw cycles and ice formation criteria. So there’s no need to worry that the chimney caps might block the escaping exhaust gases or increase the risk of soot fire. With the CE marking, Richard Brink verifies the high quality and safety standards of its products.

![[Translate to Englisch:] Erhöhte Zeltdach-Form aus Edelstahl [Translate to Englisch:] Kaminabdeckung mit erhöhter Zeltdach-Form](/fileadmin/_processed_/6/2/csm_teaser-dach2_f70f96f661.png)