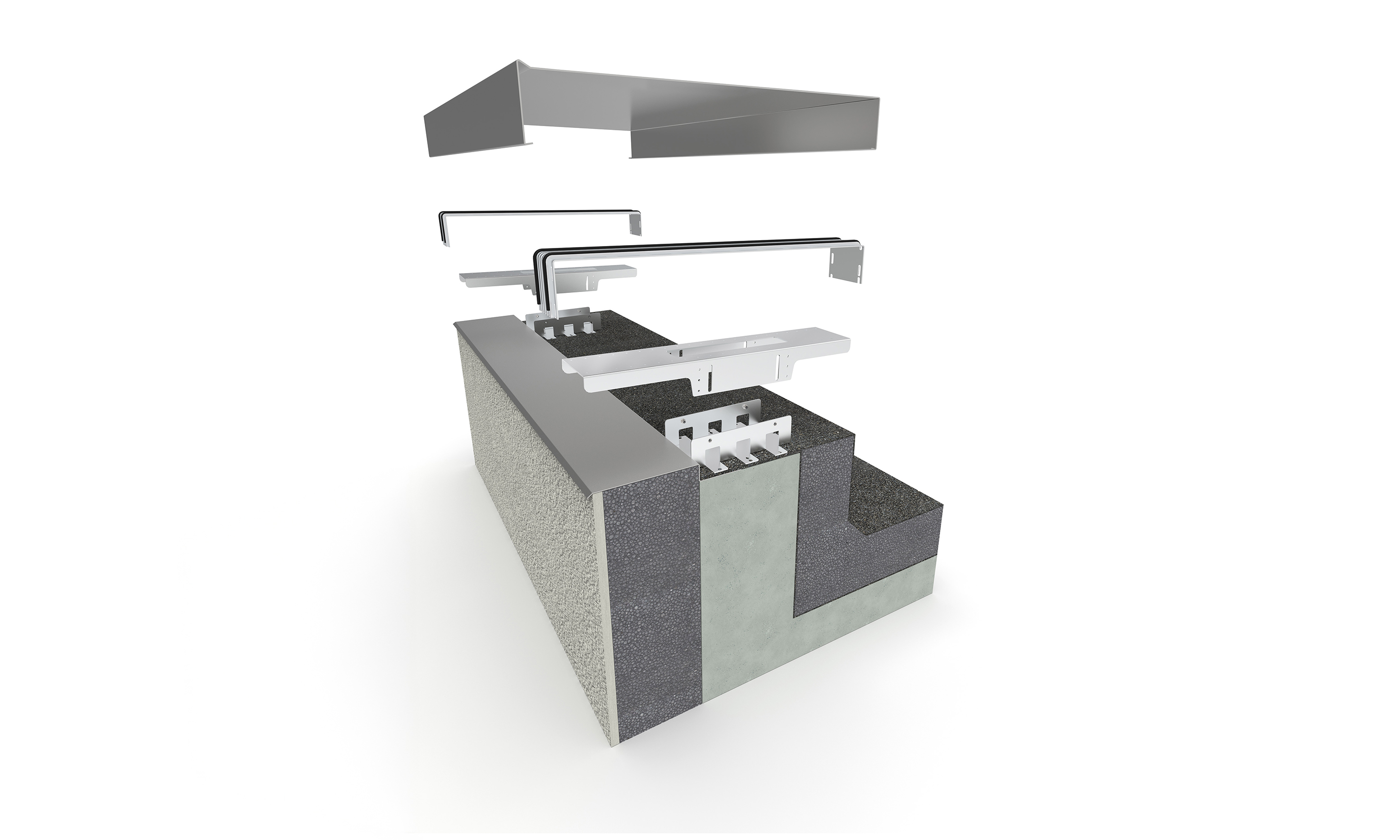

High-quality parapet coverings fitted along a roof’s edge effectively protect the building structure from moisture seepage caused by precipitation. The company Richard Brink produces its custom-made Cavor edge profile system with this in mind. Besides the metal cover, the system is always supplied with rubber lip holders that connect to the roof edge. The edge profiles are then clicked into place over the holders. The metal products manufacturer therefore provides its customers with a bespoke and precisely-fitting all-round package.

Product evolution: problem solver

The selection of products for parapet coverings has now been expanded to include the Cavor Flex model. The product innovation functions as a height-adjustable substructure and, together with the rubber lip holders, forms an interface between the masonry and the edge profile. In the past, corresponding wooden planks that sloped towards the roof surface had to be mounted to create a substructure. The rubber lip holders were then fixed over the wood. From now on, the Cavor Flex aluminium interface can be screwed directly to the wall at specific intervals. Not only is the material saving sustainable, it also simplifies time-consuming preparation and installation work on site.

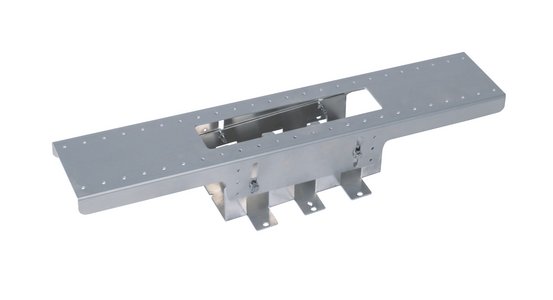

The height-adjustable mount is made up of two U-shaped profiles. The bottom profile is screwed to the brick or concrete wall. The top profile is steplessly adjusted in height using two screws and compatible, specially designed slotted holes. This determines not only the height but also the gradient of the subsequent edging. The height-adjustable profile can be set at between 60mm and 95mm high, whereby a gradient of two degrees is easily achieved. Adjusting the height opens up spaces between the substructure and the masonry, which can simply be filled with additional insulation material. The projecting sections of the height-adjustable mount are generally available in a variety of designs to cover a range of façade superstructures. No matter how thick the insulation and façade materials are, we have the right mounts with corresponding projections to fit every structural condition. We can also cater to custom measurements.

An optional cover profile helps save even more time. It can be screwed directly to the roof edge and creates a projection on the façade side. The profile helps build an initial seal along the edge of the roof. The cover plate aids the plasterer or bricklayer by acting as a protection and rebate profile for the subsequent insulation layer and façade. As the insulation and façade materials are to be added below the profile, work on the façade and also on the parapet covering can be carried out in parallel or separately.

Hand in hand towards a new transition

The construction of the height-adjustable Cavor Flex is perfectly attuned to the rubber lip holders produced by Richard Brink, which can be precisely screwed on top of the new substructures. The rubber lip holders themselves are groove profiles, which also serve as a mount and connector in one. The holders and their adjoining substructure are attached to the parapet at regular intervals, wherever the edge profiles join together. Rubber lips are pre-mounted into the two outermost grooves. They create a gap between the edge profile and the clip fixture and seal the joint area between the cover elements. Any water that gathers at the profile joints is collected in the rubber lip holder’s central grooves, shielded by the lips themselves, and directed down the gradient towards the roof.

All edge profiles made by the metal products manufacturer are produced to fit the exact dimensions of the respective roof edges, whereby one section can measure up to 3 metres in length. Customers can enter their specific measurements into the specially developed edge profile configurator available on the Richard Brink website. They will then receive a ready-to-order summary of the edge profiles that are to be custom made, including all the relevant product accessories.

(approx. 4,590 characters)